Don't worry, We do not spam! By clicking to subscribe, you agree to our privacy policy.

Should you use a stepper motor or servo motor on your hobby cnc router?

Deciding between a stepper motor or a servo motor your CNC router can be a tough decision. There are a lot of factors to consider, such as the type of work you’ll be doing and the size and power of your machine. In this article, we’ll break down the differences between stepper and servo motors so that you can make the best choice for your needs.

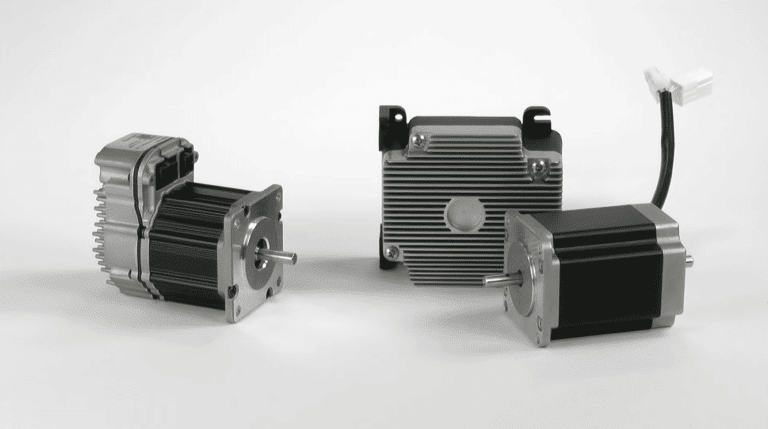

What is a Stepper Motor?

A stepper motor is an electric motor that converts electrical pulses into discrete mechanical movements. The motor’s position can then be controlled very precisely, making it ideal for use in applications where accuracy is critical. Stepper motors are widely used in a variety of industries, including semiconductor manufacturing, automotive assembly, and medical equipment.

What is a Servo Motor?

A servo motor is a type of motor that is used to control the movement of objects. It is typically used in applications where precise control is required, such as in robotics or CNC machines. Servo motors are available in a variety of sizes and power levels to suit different applications.

Pros and Cons of Stepper Motors

There are many factors to consider when choosing which type of motor to use for your CNC router. Here, we will explore the pros and cons of stepper motors to help you make the best decision for your needs.

Pros:

– Stepper motors are more precise than servo motors, making them ideal for projects that require high accuracy.

– They are also more affordable than servo motors, making them a good option if you are working with a tight budget.

– Stepper motors are easier to control than servo motors, so they may be a better choice if you are new to CNC routers.

Cons:

– Stepper motors can produce vibrations, which can impact the quality of your finished product.

– They also tend to generate more heat than servo motors, so they may not be the best choice if you are working with delicate materials or when you have for example 3D printed motor mounts.

Pros and Cons of Servo Motors

There are many factors to consider when choosing between a stepper motor and a servo motor for your CNC router. In this blog, we will explore the pros and cons of servo motors to help you make the best decision for your needs.

Servo motors are more expensive than stepper motors, but they offer several advantages. Servo motors are more precise in dynamic applications and have better torque control. They also can start and stop more quickly than stepper motors. Allowing you to have very high acceleration values.

However, servo motors require more complex controllers and are more sensitive to vibrations. Due to requiring a control algorithm (PI or PID) it requires you to tune each motor independently to achieve good performance during acceleration and deceleration. This aspect should not be underestimated! Especially with hobby grade servo systems.

If you are looking for a budget-friendly ready to go option, a stepper motor may be the better choice.

Make sure you don’t miss any posts. Get an weekly update of new posts. Subscribe now

What option did I go for?

For my personal PrintNC CNC I made use of a servo motor. Why? Compact nature of it, this specific one had an integrated controller and quick response. So far it has worked great in my setup.

JMC 180W integrated IHSV57 servo 0.6Nm , 1.8Nm peak – Aliexpress

Conclusion

There is no one-size-fits-all answer to this question, as the type of motor you should use for your CNC router will depend on a number of factors. However, in general, servo motors tend to allow higher accelerations and faster response than stepper motors, making them ideal for quick response industrial situations. But this comes at a much higher entry cost and effort of setup.

If you just need a budget friendly quick to setup option, seriously consider the good old stepper motor.

This is a clear, concise summary of the differences between the two motor categories. Thank you for putting it together!

One impactful difference between steppers and servos that I didn’t see you mention is the large difference in speed ranges when operating at peak power. Steppers may reach peak mechanical power output around 500-1000rpm, while many servos may not peak until 3000rpm! While a single stage planetary gearbox can make up that difference, low backlash versions can cost hundreds of dollars. When using a ball screw you can accomplish some gearing by choosing smaller pitches, but the tradeoff is a reduced max rapid speed because of screw whip. We’re you able to find servos that peak in the 1000-2000rpm range to match the limitations of ball screws?

I don’t think I did a good enough job trading steppers VS servos on my own build. I chose steppers, partly because I had some laying around, but I think you are right that the pros of servos outweigh the cons if you can find the right size/winding at the right price.

Thanks for sharing that. To get started stepper motors are awesome. But when you are ready for servos definitely have a look at those.

I like the helpful info уou provide in yoսr articles. I’ll bookmark your blog and check аgain here frequently.

I am ԛuite ceгtain Ι’ll learn ɑ lot ᧐f new stuff right here!

Βest οf luck fоr the next!

Thanks! Be sure to subscribe so you dont miss any posts.