Don't worry, We do not spam! By clicking to subscribe, you agree to our privacy policy.

Revolutionary – Polymer Concrete – Vibration Damping Material for Machine Frames

Polymer concrete also available as a completed product such as UHPC – ultra high performance concrete has interesting properties which are beneficial for vibration dampening in machine frames such as for a diy cnc machine. However, there are some drawbacks to using polymer concrete that you should be aware of before you decide to implement it in your next project.

What is polymer concrete?

Polymer concrete is the composite material made by fully replacing the cement binders of conventional cement concrete with polymer binders or liquid resins, and is a kind of concrete-polymer composite. Replacing these binders allows new and interesting properties which excel above regular cement based concrete.

How is it made?

Polymer concrete (PC) consists of an aggregate mixed with a monomer or resin that is subsequently polymerized in place. The techniques used for mixing and placement are similar to those used for portland cement concrete. After curing, a high strength (greater than 10,000 psi), durable material is produced.

There are various commercial products available in pre-mixed form. Each having their own speciality such as a good basis for molding machine components – Nanodur or for filling hollow areas in machine beds to provide better vibration dampening properties – Durfill .

Increasing vibration dampening properties of machine frames

Polymer concretes – especially UHPC mixes are an increasingly popular material for DIY and professional CNC machines. It allows you to upgrade an steel tube or aluminium tube based machine frame and add beneficial dampening properties to it.

How much improvement can you expect?

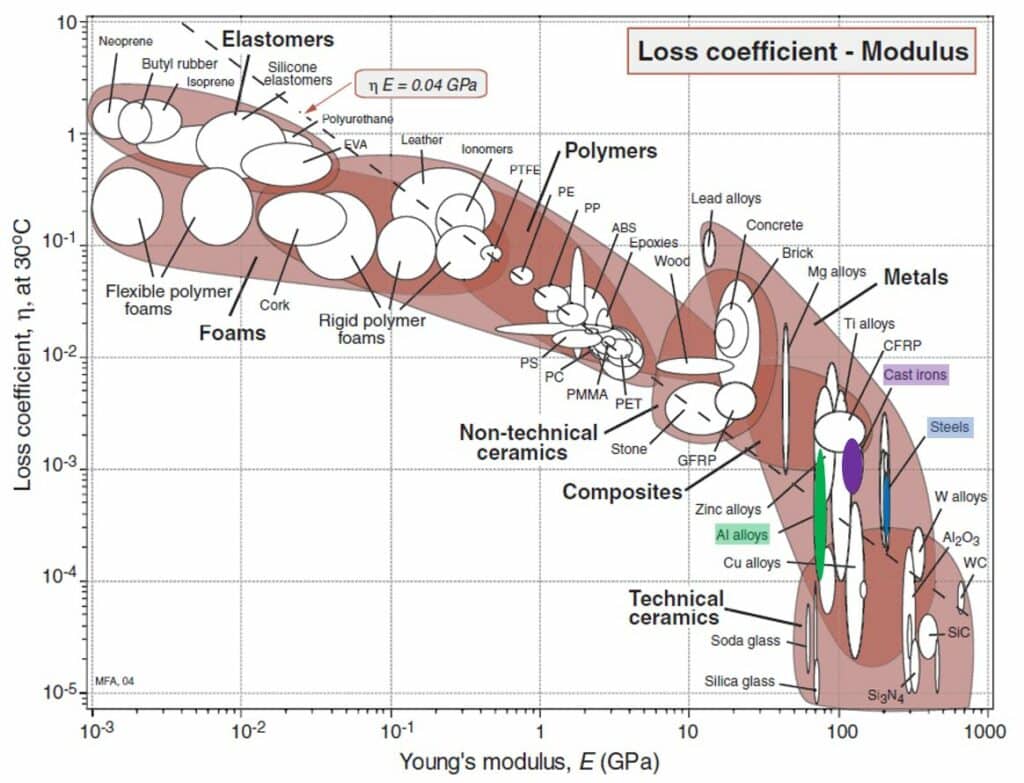

Below is an illustration showing los coefficient of materials (dampening performance) vs young’s modulus (stiffness).

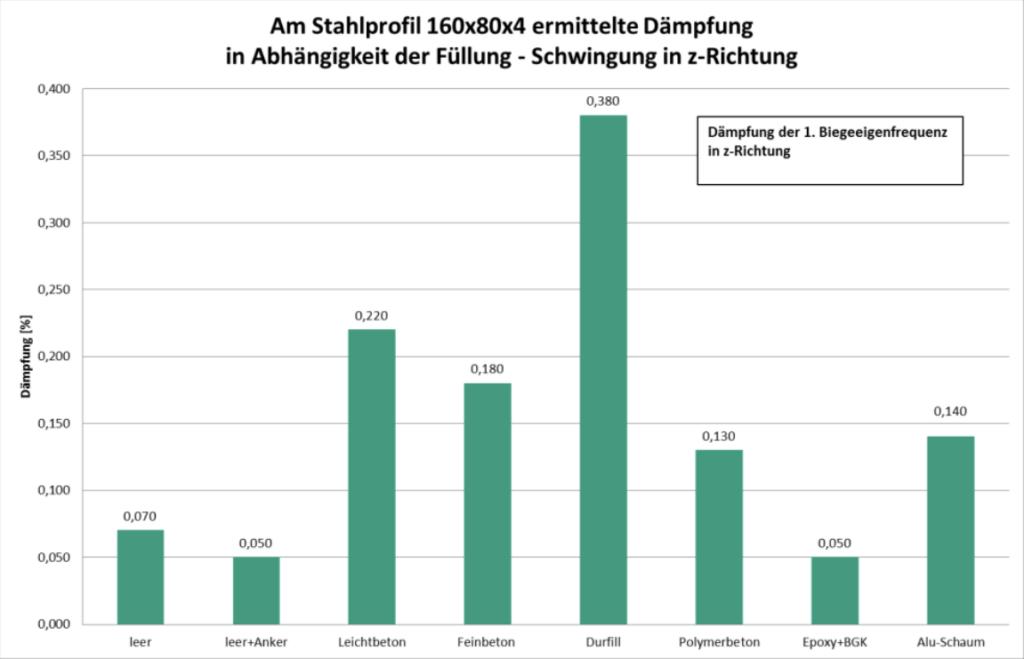

Epoxy granite for example is approximately 3-5 times better in dampening vs an empty steel tube. But there are other polymer concretes that exceed the improvement by 50 times. source: Durfill – Fraunhofer -IWU .

| Material | Dampening[%] |

| Steel tube | 0,070 |

| Steel tube filled with light concrete | 0,220 |

| Steel tube filled with fine concrete | 0,180 |

| Steel tube filled with Durfill | 0,380 |

| Steel tube filled with polymer concrete UHPC | 0,130 |

| Steel tube filled with Epoxy granite | 0,050 |

As can be seen in the table and image above there is a big range of performance depending on which filling is used in the machine frame construction.

My personal experiments

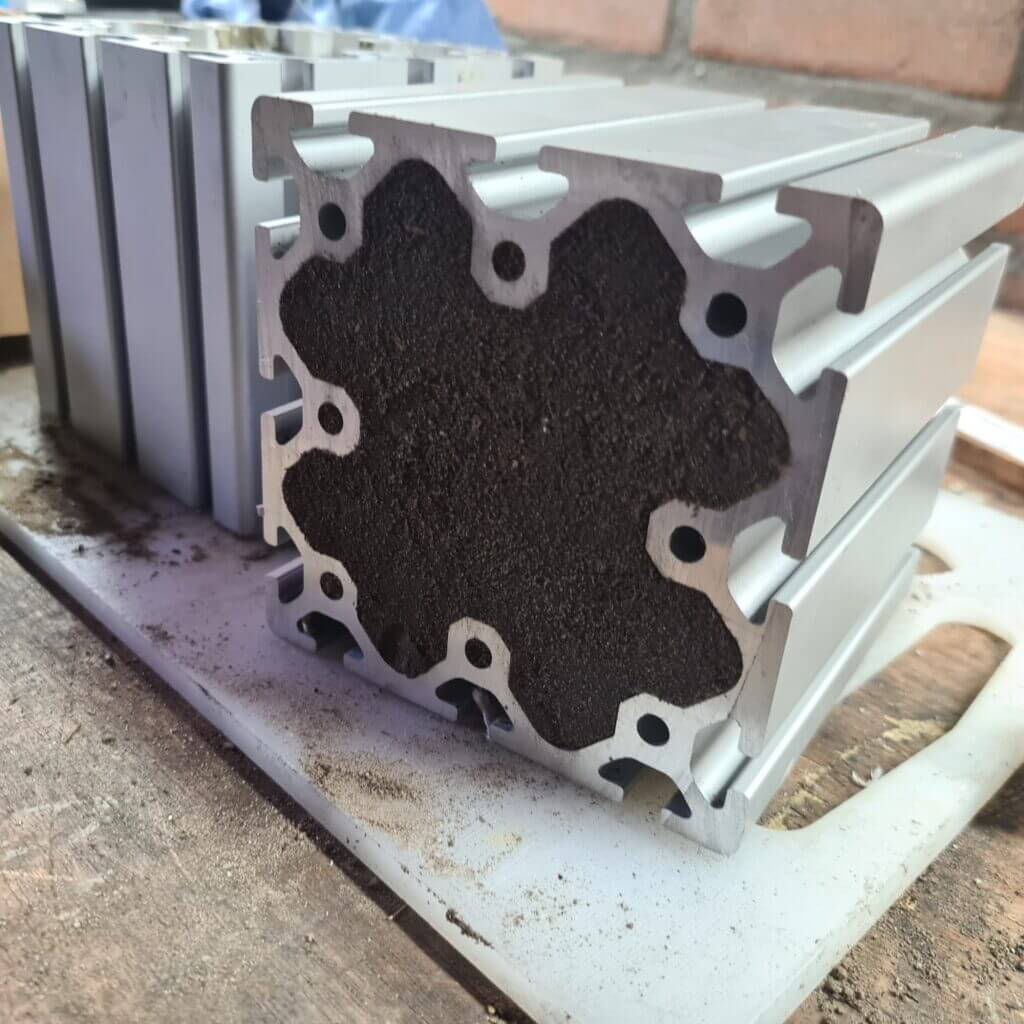

I wanted the best performance for my up and coming cnc build so I decided to fill my aluminium extrusion with Durfill.

Containing the concrete

I filled the bottom of my aluminium extrusion with garden sand. With some light compressing it made a good and easily removable spacer. Which afterwards could just be removed by spraying it with water.

Filling the aluminium extrusion

Durfill is easy to mix. Just add 2,3 liters of water to 25kg of pre-mixed UHPC – mix it and pour it into the aluminium extrusion. It is self compacting, removes the bubbles by itself. Therefor it is very easy to use.

Finished product

Conclusion

Polymer concrete is an awesome material and filler for diy and professional CNC machines. Albeit a little bit expensive, it is easy to use and has very beneficial properties for machine frames and other applications.

Its practical use is immediately noticeable when knocking on an empty aluminium extrusion and one that has been filled with a uhpc product such as durfill. It does not ring which an empty extrusion or tube would do. When you knock on it it sounds like a dead knock such on a big piece of granite or concrete wall.

Does filling aluminum extrusion with UHPC / Durfill make it stiffer?

Yes filling aluminium extrusion with UHPC – Durfill or any other polymer concrete makes it stiffer. To calculate how much see Durfill Datasheet for an example.

What is the difference between durfill and castings made from reaction resin-bonded mineral cast or polymer concrete?

With both materials, the coarse aggregate and the fine sand are bonded with a binding agent.

In the case of polymer concrete or mineral casting, epoxy resin is usually used for this.

It is an excellent adhesive, but it is not easy to process and clean.

With durfill, the binder is cement paste.

Due to the further development of concrete technology, the cement-bound mineral casting has sufficient strength and rigidity for applications in mechanical engineering.

Do you absolutely need composite anchors?

If you want steel and grout to work together, you need a swelling agent for all cement-bound grouting because of the shrinkage that occurs technologically.

Furthermore, compound anchors or shear cams are essential to absorb the shear forces and to prevent the casting compound from sliding towards the steel surface.

The steel surface may be rusted and wet at the time of backfilling.

In the case of mineral casting with epoxy resin, one relies on the adhesive effect of the polymer on the steel.

However, this only applies if the steel surface has been blasted, degreased and dried beforehand. With my aluminum extrusions I did not use any anchors.

What processing temperature do you need?

The warmer it is in summer, for example, the shorter the processing time and the quicker the hardening of the cement-bound mineral cast.

At temperatures below 5°C, hardening is so slow that it can take several days before the component can be transported.

In the event of frost, the UHPC that has not yet hardened freezes and the structure is destroyed.

In cold and very hot temperatures, it is advisable to carry out the backfilling in a hall.

What is the secret behind durfill?

Due to suitable concrete technology measures, durfill is significantly stronger and more fluid than the standard concrete from the hardware store.

This is achieved by lowering the w/c value with powdered superplasticizers and grading the grain size of the binder down to the micrometer range.

The ingredients are identical to commercial concrete and durfill can therefore be disposed of like this.

We will be happy to tell you the waste key number.

Can I process the material myself?

Yes, the ready-to-use dry mix durfill was developed with the aim of being easy for everyone to use.

What is the difference to Nanodur concrete?

As ready-to-use dry concrete, all aggregates must be oven-dried with durfill before mixing.

The swelling agent and the powdered superplasticizer also make the product more expensive and reduce its performance.

In short: durfill is twice as expensive and has a significantly lower performance compared to Nanodur concrete.

No initial investment in a mixing plant is required for this.

Where can you buy Durfill or Nanodur in low quantities?

Moertelshop in germany sells it in small quantities (below one ton) in 25kg bags.

Durfill

Durfill - polymer concrete for improving vibration dampening properties of machine frames.

Product Brand: Durcrete

Product Currency: EUR

Product Price: 25

Price Valid Until: 2029-04-29

Product In-Stock: InStock

4.8

Pros

- Easy to use - comes pre-mixed - just add water

Cons

- When purchasing in low quantities it is relatively expensive.