Don't worry, We do not spam! By clicking to subscribe, you agree to our privacy policy.

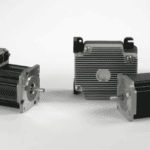

88$ JMC IHSV57 180W DC servo motor

Are you looking for a low-cost servo motor for your DIY CNC machine? The JMC IHSV57 180W DC servo motor may be the perfect choice for you. This servo motor has gained popularity in the DIY CNC field in recent years for its quick rapids and potential for increased accuracy.

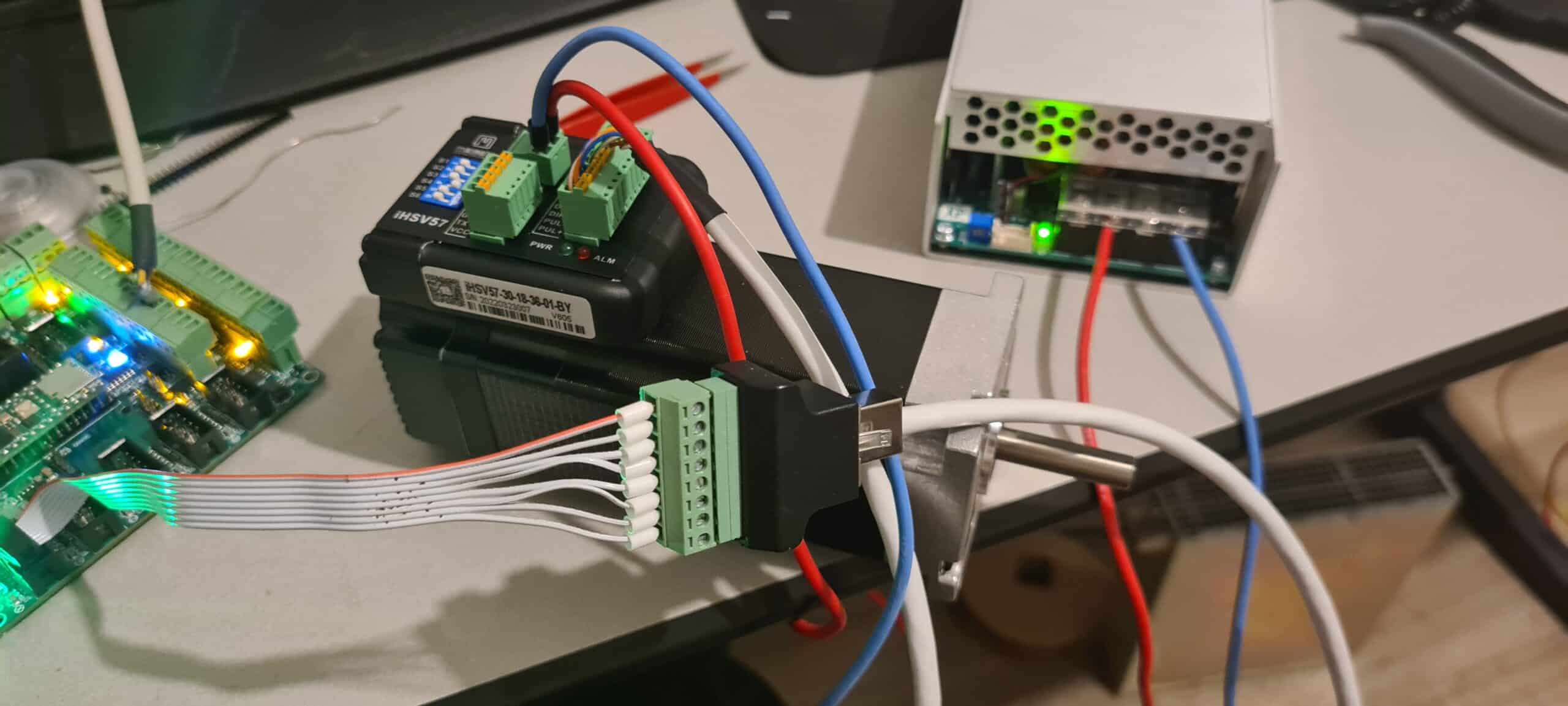

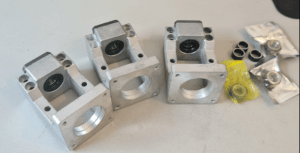

When you unpack the JMC IHSV57, you’ll find that it is well-packaged in a sturdy box with ample foam padding.

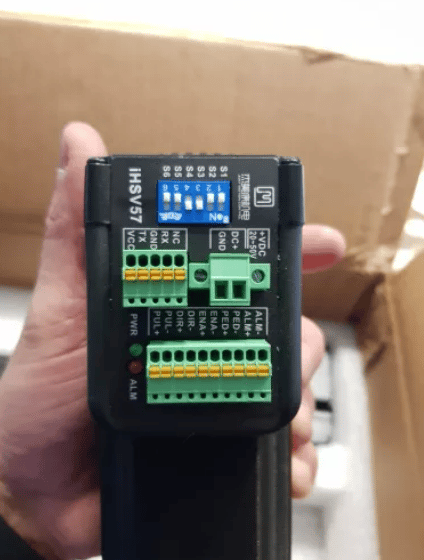

The motor itself feels heavy and well-constructed, with “phoenix” style plug-and-play connectors for power, control, and communication signals.

The power connector has screw terminals to prevent it from coming loose during installation or use.

The mechanical construction of the JMC IHSV57 also feels sturdy and professional.

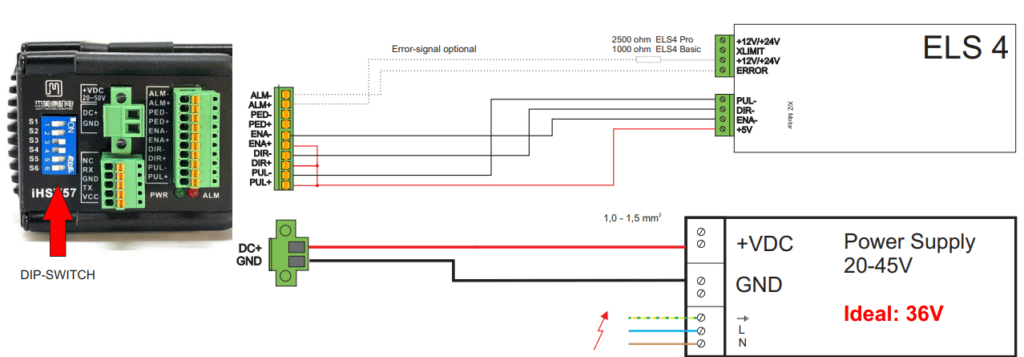

To connect the JMC IHSV57 servo motor, you can use the connection diagram provided by the manufacturer.

You can find the connection diagram here *I do not use the ELS 4 controller but GRBRLHAL2k*

For a neater and easier to manage connection, you can use shielded flexible ethernet cable to connect the servo/stepper signals to your CNC controller. This helps to reduce EMI and EMC issues.

This made the connection very easy and clean. The twisted pairs and double shielding of the CAT5 ethernet cable helps enormously against EMI and EMC issues. I really recommend using it. You can find the 8 wire to ethernet adapter from Aliexpress here

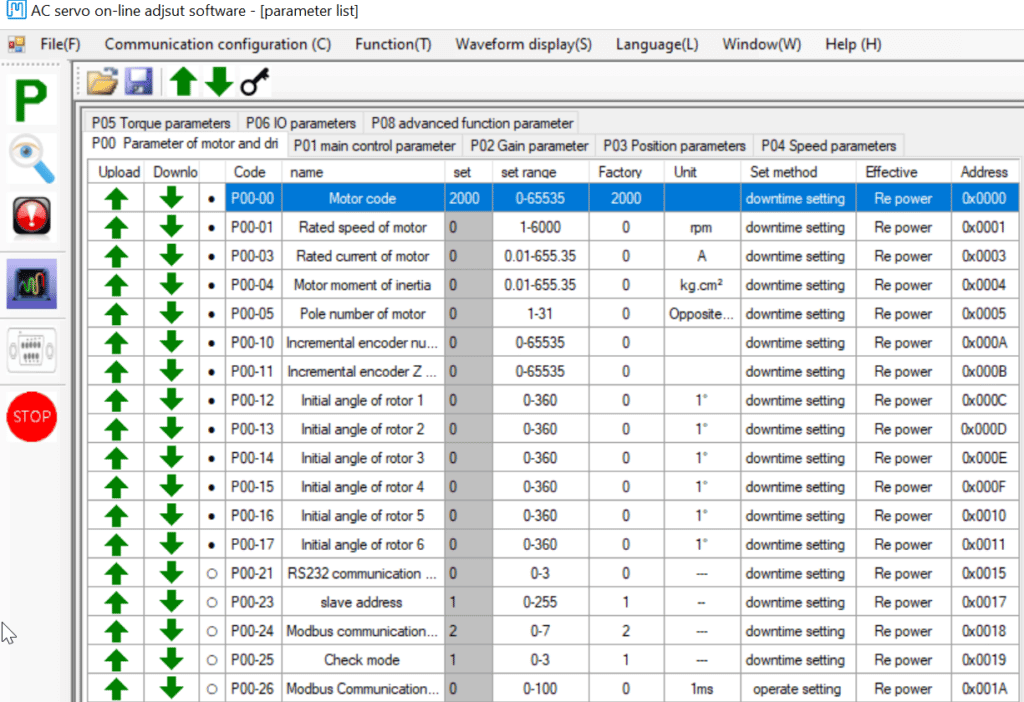

Tuning the JMC IHSV57 servo motor can be a bit more challenging than with more expensive controllers, but there are resources available to help you. Videos such as those listed in this article can provide helpful guidance for initial autotuning and further understanding of the tuning process.

Where you would get 80-90% there while using “proper” autotuning algorithm from a more professional but also much more expensive servo controller, with the JMC servo control software it is a bit more work.

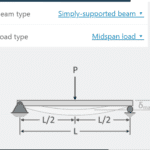

Normally I would use resources such as the National Instruments – Understanding servo tuning guidelines.

But for the JMC servo tuning I found the following resources the best to get started on tuning your IHSV57 servo:

This first video gets you going with the initial autotuning.

The second video got gave me a lot extra background information and allowed me to tune my IHSV57 servo motors well.

These are the most frequently asked questions related to the JMC IHSV57 180W DC servo motor.

How to tune IHSV57 servo

What helped me the most is the videos posted in this article by JB Worx Studio.

Where can I find the JMC IHSV57 Manual

The user manual of the IHSV57 can be found here

Where can I find the JMC servo control software?

The control software for the IHSV57 servo series can be found here

Should I get a servo motor or stepper motor for my DIY cnc

This is not an easy question. There are many pro and cons when making this choice. In this article we talk about this subject in detail.

How to fix JMC servo control connection issues

Initially I had some serious problems getting connected to the JMC IHSV57 servo motor through the JMC servo controller software. When I purchased a premium RS232 UGREEN cable it fixed my issue.

Conclusion

Overall, the JMC IHSV57 180W DC servo motor is a great choice for those looking for a low-cost option for their DIY CNC machine. It may take some extra tuning effort, but the end result is a quick and responsive CNC router. Plus, at a price of just 88$ per servo, it’s a great value. Get yours on Aliexpress before stock runs out.

JMC IHSV57

Are you looking for a low-cost servo motor for your DIY CNC machine? The JMC IHSV57 180W DC servo motor may be the perfect choice for you. This servo motor has gained popularity in the DIY CNC field in recent years for its quick rapids and potential for increased accuracy.

Product SKU: IHSV57

Product Brand: JMC

Product Currency: USD

Product Price: 88

Price Valid Until: 2022-09-23

Product In-Stock: InStock

4

Pros

- Relatively affordable

- Good support

- Quick and responsive dc servo motor

Cons

- Autotuning could be better

- Documentation could be better

Hi spikee, I am enjoying the website and your newsletter. I have also been following you on the PrintNC Discord server as well! 🙂 I was wondering if you could write an article on the purpose and need for a servo brake when using a servo on on your Z-axis. I am seriously considering using the 180w servos for my PrintNC build but I’m still not exactly sure how to incorporate/wire a servo with a brake for the z-axis. Thanks! -William-

Hi William,

The primary use for the brake is to prevent the z-axis from falling down when you turn off the machine or press the e-stop.

On my old machine, I broke plenty of tools like that. For the IHSV57 specifically, you don’t need to actuate it manually. When you enable the drive (input) on the servo the break gets released.

Ahh, that makes sense. Thank you!