Don't worry, We do not spam! By clicking to subscribe, you agree to our privacy policy.

#1 Millalyzer the ultimate feeds and speeds tool

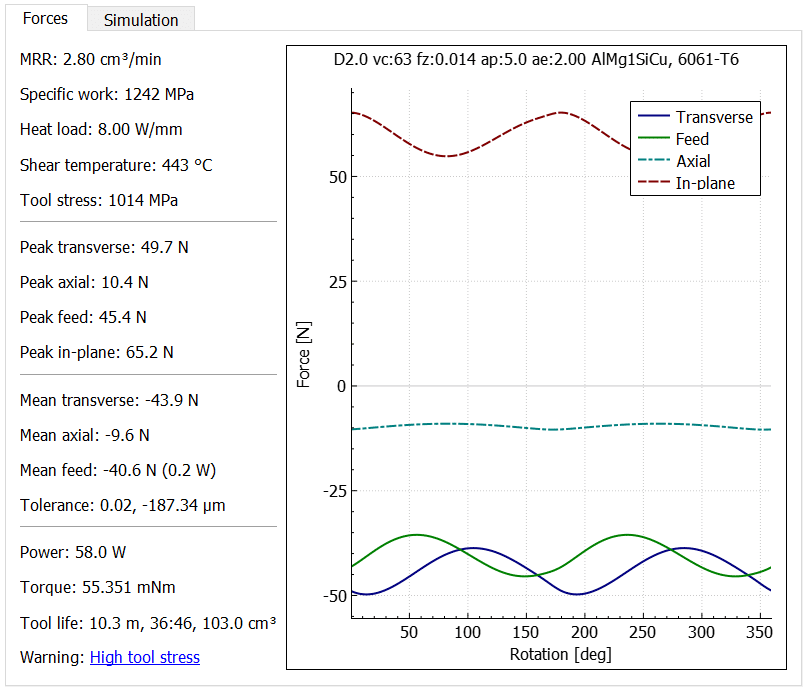

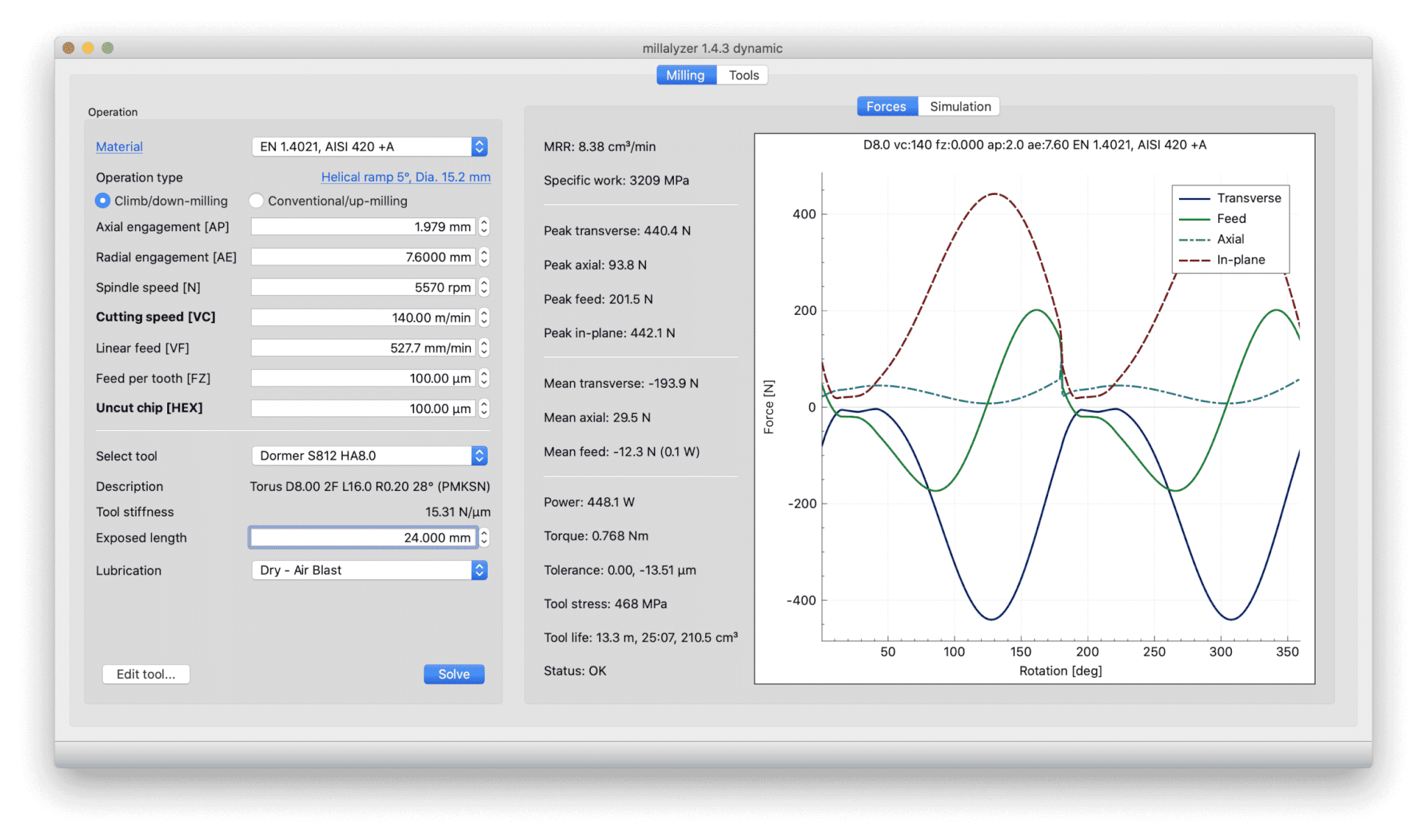

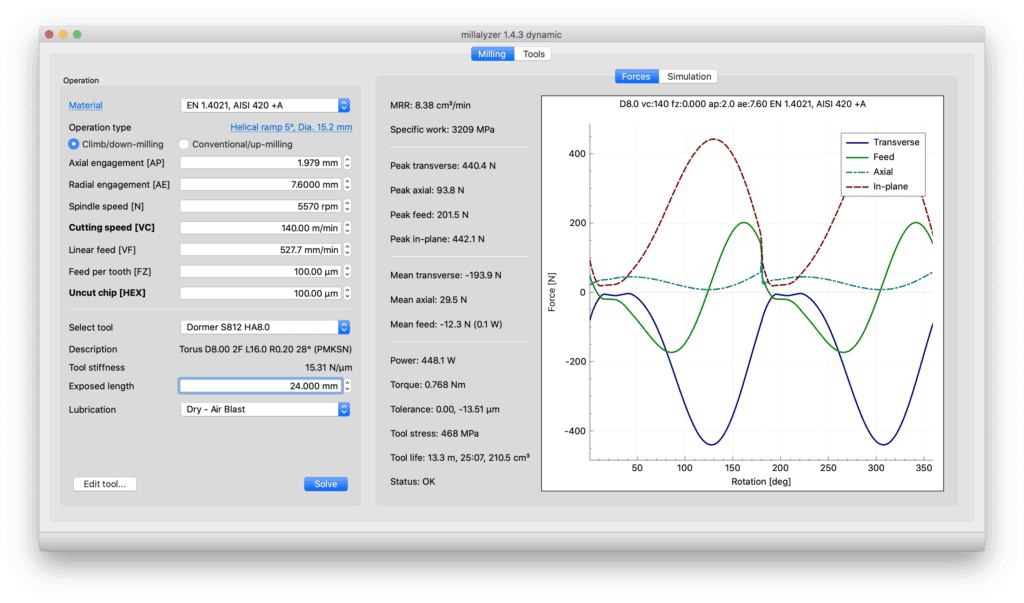

Millalyzer is the most advanced speed and feeds optimization tool that I know of. It has advanced features such as efficient force and chatter predictions using state-of-the-art numerical models. It allows you to optimize your speed and feeds on your CNC mill or CNC router for maximum material removal rate, minimum tool, and machine deflection, and for the best surface finish. I recently purchased it after completing my PrintNC build.

Milling Quietly: Tips and Tricks

In this example “I’m no expert, but” on youtube uses a Millalyzer like tool to figure out how to mill more quietly, but also important are the mounting of the mill on your bench and the speeds and feeds you’re using. Sometimes a deeper, more aggressive cut is quieter!

Shapeoko Feeds & Speeds and Machining Tips!

In this example by NYCCNC on youtube uses a Millalyzer to optimize speeds and feeds, reduce chatter and increase workfishsh thus reducing cost of an automotive part. Calculate shapeoko hdpe feeds and speeds by utilizing this tool.

Below is a quick how-to on how to calculate speeds and feeds on a cnc router. To use the calculator and figure out cnc speed and feeds that fit your machine such as the Nomad 833 or Onefinity cnc or Shapeoko HDZ.

How to calculate speeds and feeds cnc router

-

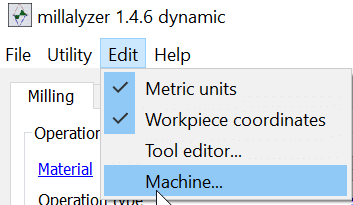

Select the correct machine

Open Millalyzer -> go to Edit -> select Machine

-

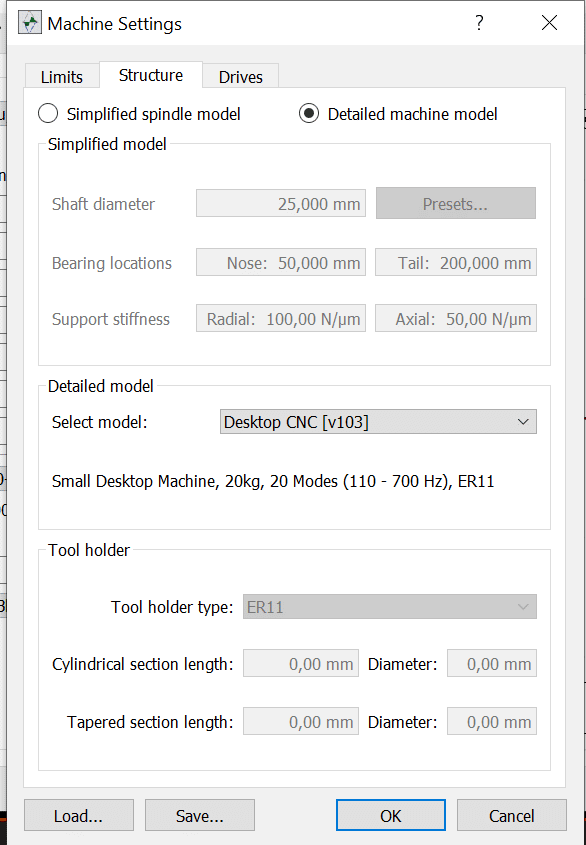

Select the preset model

Use the preset “select mode” Desktop CNC in case you are running a machine like the Nomad 833 or Onefinity cnc or Shapeoko HDZ . This gives a good staring point for calculating speeds and feeds. You can always override the settings later if you want to adjust it up or down. After selecting press ok.

-

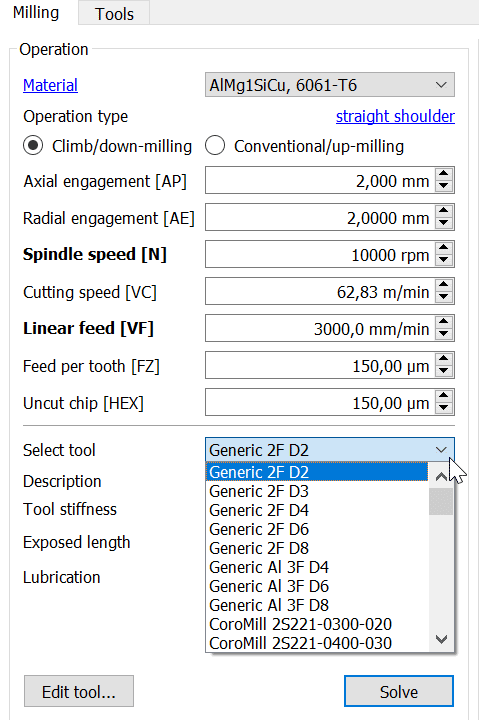

Select material and tool from the tooltable

In this specific example I selected a Generic 2 flute 2mm diameter bit.

As the material for the Shapeoko pro or Shapeoko hdz I chose generic aluminium -

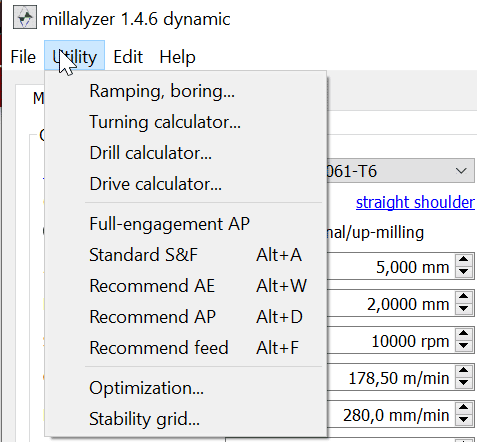

Calculate standard speed and feeds for your cnc router

Either go through the menu Utility -> Standard S&F or use the shortcut Alt+A to calculate the standard feeds and speeds for your diy – cnc router.

-

Play around with the settings

Millalyzer has many settings you can use to optimize a cut for a specific material or situation.

The primary goal is to keep the cutting force within the allowable forces of your specific cnc router . For example on a Nomad 833 the allowable forces will be much lower than a Onefinity cnc or the Shapeoko HDZ or Shapeoko Pro style of machines.The main goals for this would be to:

– Reduce chatter (milling forces within the parameters of your machine)

– Reduce or increase the torque of your cnc spindle depending if it is bogging down or can use some more cutting forces.

– Eliminate high tool stresses -> prevent tools from snapping

– Optimize material removal rate – MRR in case you want to speed up your cuts

– Reduce or increase heat load in the tool or material

– Reduce noise of your diy cnc by optimizing tool geometry and cutting strategy to enable constant cutting forces. Example Here

Tools:

- Millalyzer

Is Millalyzer free?

No, millalyzer is a paid tool. However you can try it first here

How much does millalyzer cost?

Millalyzer comes in two flavors. Millalyzer static and Millalyzer dynamic. The cost of it is at this moment 29 euro and 59 euro incl. VAT.

What features does Millalyzer static have?

– predict cutting forces reliably

– find optimal cutter engagement values

– define machine & spindle constraints

– warn for premature tool failure

What features does Millalyzer dynamic have?

In addition to the features of Millalyzer static:

– simulates elastic tool motion;

– helps to avoid excessive chatter.

Where can I find the Millalyzer user manual?

The documentation and user manual can be found here

Who runs Millalyzer?

Millalyzer is being run by Larosterna ab based in Sollentuna Sweden.

The creator is David Eller – https://www.larosterna.com/contact

Conclusion

Personally I was quite impressed after hearing about Millalyzer and I proceeded to buy a license for it. I always wondered how many forces were on an end mill , how much heat was introduced and what kind of power the cnc spindle motor would use for a cut. While I used tools such as Gwizard and Fs wizard before, I found the Millalyzer tool much more detailed, understandable and easier to use.