Don't worry, We do not spam! By clicking to subscribe, you agree to our privacy policy.

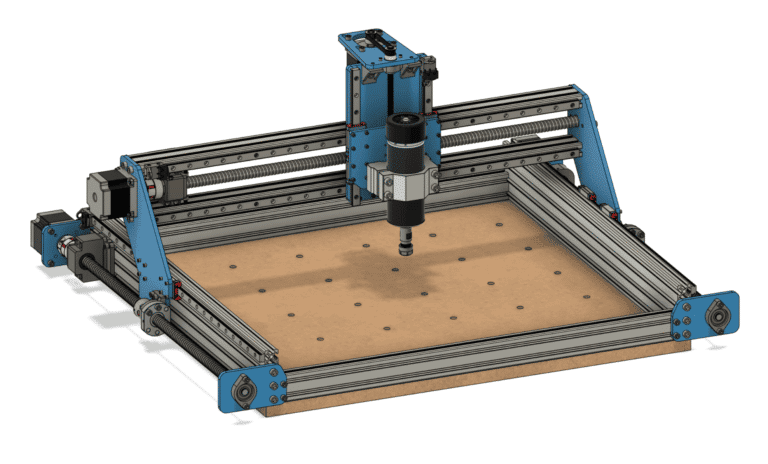

INDYMILL – Easy DIY OPEN SOURCE METAL CNC MACHINE

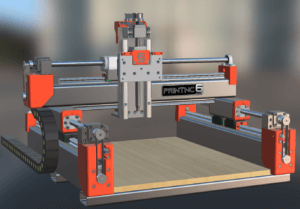

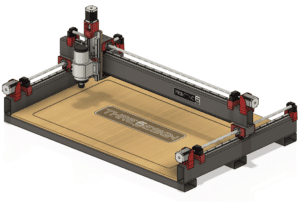

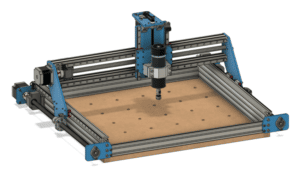

IndyMill is a project started by Nikodem Bartnik as an upgrade of Dremel CNC machine. The basic idea behind this project is to create easy to build CNC machine that anyone around the world can reproduce. Using popular, easily available components is only one of many challenges on the road. Great documentation is just as important as good design, those two have to come together to create an outstanding project and that’s the goal. Below You can see up to date list of videos and some pictures of this project, together with files and parts list.

Parts list

Below you can find tables with all the parts that I used to build IndyMill. The table is divided into mechanics and electronics if you prefer an excel sheet that you can easily print, export, and open on your computer you can find it here:

Excel sheet – IndyMill Parts

IndyMill build based on this parts list has a working area of about 520x400x115mm. The outside dimensions are 760x660x360mm. Of course by using longer profiles, linear rails and ballscrews you can build it bigger.

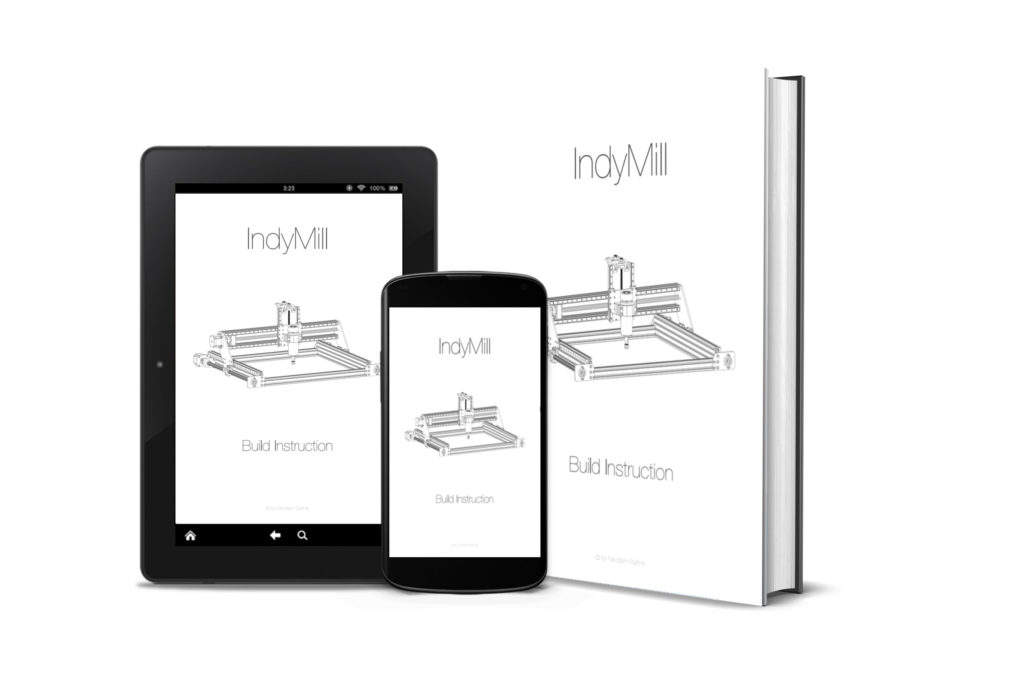

Build instruction

The above parts list and files down below is everything that you need to build the IndyMill. It’s open-source so you don’t have to pay anything for the files or design. But I thought that I will make a detailed instruction so that it will be easier for some of you to assemble this project and at the same time support my work. It’s 40 pages long, there are over 60 drawings and a lot of useful information on the assembly process. It’s a PDF file so you can put it on your computer, smartphone, tablet or even print. And it’s only $10. Let me say it again, you don’t need it to build this project, but if you want to simplify the assembly process and support my work at the same time, you can get the instruction here:Buy on

Essential parts

Videos

Here are all the videos that I made about IndyMill (plus updates below). I highly advise watching all of them before starting building one. There is a lot of useful information in each one of them and step by step assembly process showed. Also, you can take a closer look at fails, design process, and some problem-solving

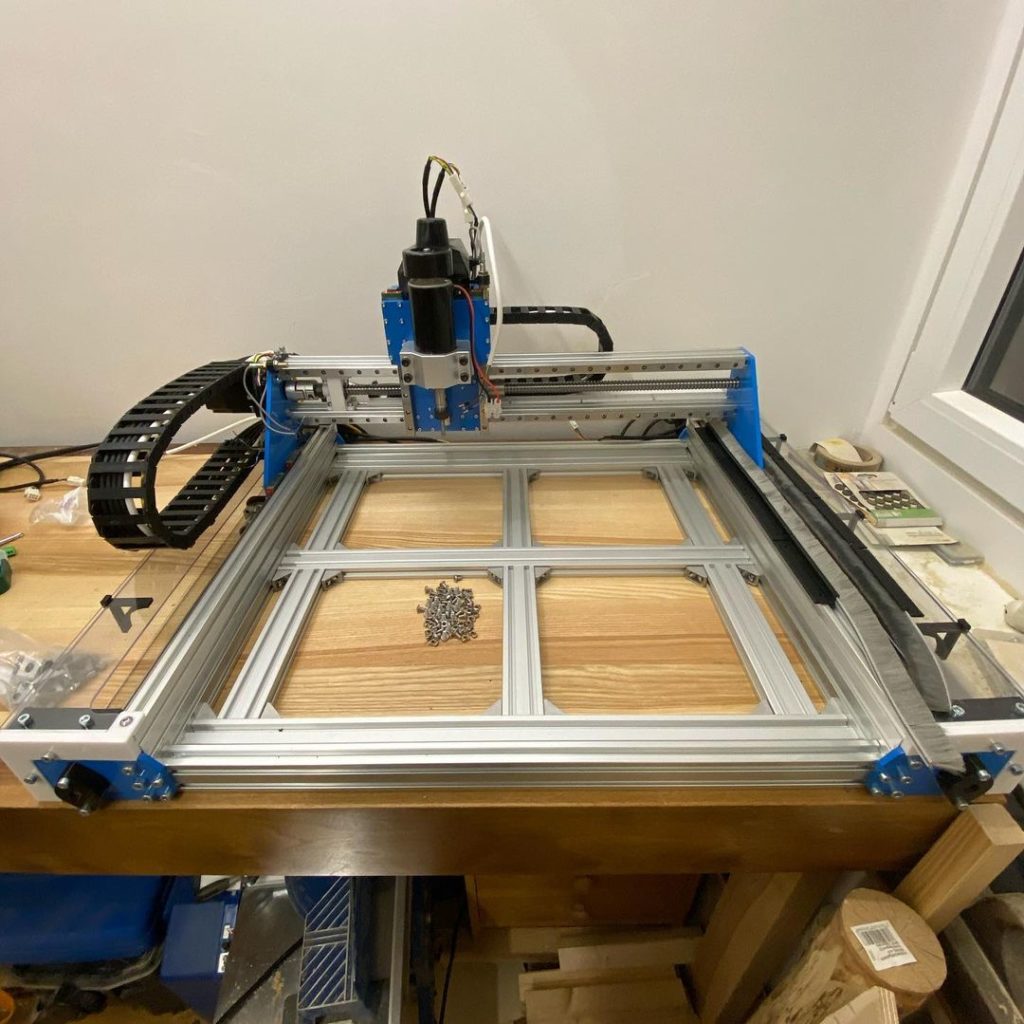

Built by the community

Below you can find pictures of IndyMill’s built by an awesome community of DIY enthusiasts, machinists, and makers!

IndyMill Created by Nikodem Bartnik in 2019/2020

These are the most commons questions asked relating to the Indymill

Where can I find the Indymill bom

The Indymill BOM also known as bill of material can be found here

Where can I find a Indymill review

Well on this page I do a quick review based on my mechanical engineering knowledge. The best way to figure out if the Indymill is suited for you application is by checking relevant youtube videos.

Where can I find the Indymill build instruction pdf

The build instructions are a paid feature. It can be bought here

Is there a Indymill kit

At this time there is no full kit available for the Indymill.

What is the Indymill price

Pricing can vary quite a lot based on what items you buy but the final pricing should be around 1000$

Indymill

IndyMill is a project started by Nikodem Bartnik as an upgrade of Dremel CNC machine. The basic idea behind this project is to create easy to build CNC machine that anyone around the world can reproduce. Using popular, easily available components is only one of many challenges on the road. Great documentation is just as important as good design, those two have to come together to create an outstanding project and that’s the goal. Below You can see up to date list of videos and some pictures of this project, together with files and parts list.

Product Brand: Indymill

Product Currency: USD

Product Price: 999

Price Valid Until: 2022-09-22

Product In-Stock: InStock

3.5

Pros

- Suitable for wood and plastics

- Low cost of entry

- Open source

Cons

- Not suitable for (semi) serious aluminium milling