不用担心,我们不会发送垃圾邮件!点击订阅即表示您同意我们的 隐私政策.

避免?环氧树脂花岗岩用于DIY数控

环氧树脂花岗岩是一种在 DIY CNC 社区中因其易用性和阻尼特性而备受关注的材料。但是,在您决定为您的下一个 CNC 构建改用它之前,您应该了解使用环氧树脂花岗岩的一些缺点。

什么是环氧花岗岩?

环氧花岗岩又称聚合物混凝土,是一种由环氧树脂和花岗岩骨料混合而成的材料。它通常用作建筑材料或用于制作台面、地板和其他表面。环氧花岗岩坚固耐用,几乎可以成型和模压成任何形式。它还耐热、耐化学品和耐冲击,并具有有益的阻尼特性。

它是如何制作的?

环氧花岗岩是一种由环氧树脂与花岗岩粉/骨料结合而成的材料。它是一种坚固耐用的材料,通常用于制造台面和其他表面。

环氧花岗岩有什么好处?

环氧花岗岩是一种越来越受欢迎的 DIY 数控机床材料。它坚固耐用,但相对较轻(与钢相比)且易于使用。此外,环氧花岗岩不导电,具有出色的减振性能,非常适合用于 CNC 应用。

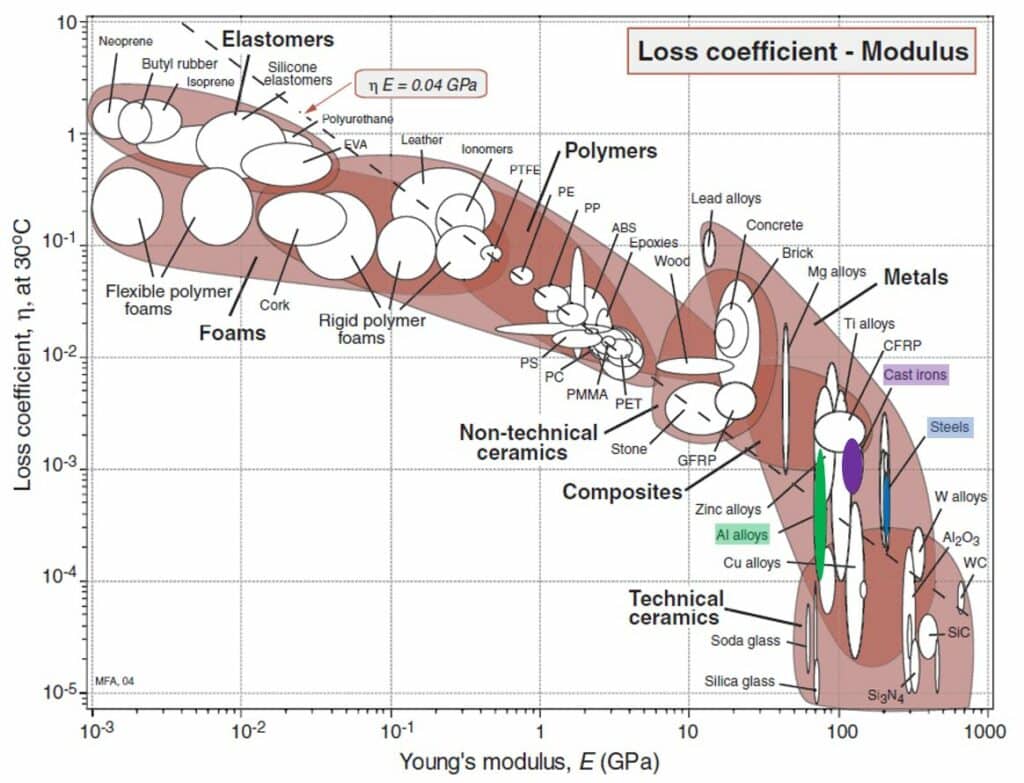

虽然它以其阻尼特性而闻名……但实际上它与替代品相比并不是那么好。为了说明见下图:

因此,虽然它在阻尼方面比空钢管好大约 3-5 倍。还有其他替代方案超过 50 倍。资源: 杜菲尔-弗劳恩霍夫-IWU .我将写一篇关于什么是阻尼、哪些材料具有哪些特性等的帖子。

最后,如果您没有经验,环氧树脂花岗岩可能很难使用。它需要特殊的工具和技术来确保良好的最终结果。

确保您不会错过任何帖子。获取每周更新的新帖子.现在订阅

环氧花岗岩的替代品有哪些?

环氧树脂花岗岩是 DIY 数控机床的流行材料,但它不是唯一的选择。其他材料,如 UHPC 或其他聚合物混凝土也可用于制造 CNC 机床。每种材料都有自己的优点和缺点,因此为您的项目选择合适的材料很重要。

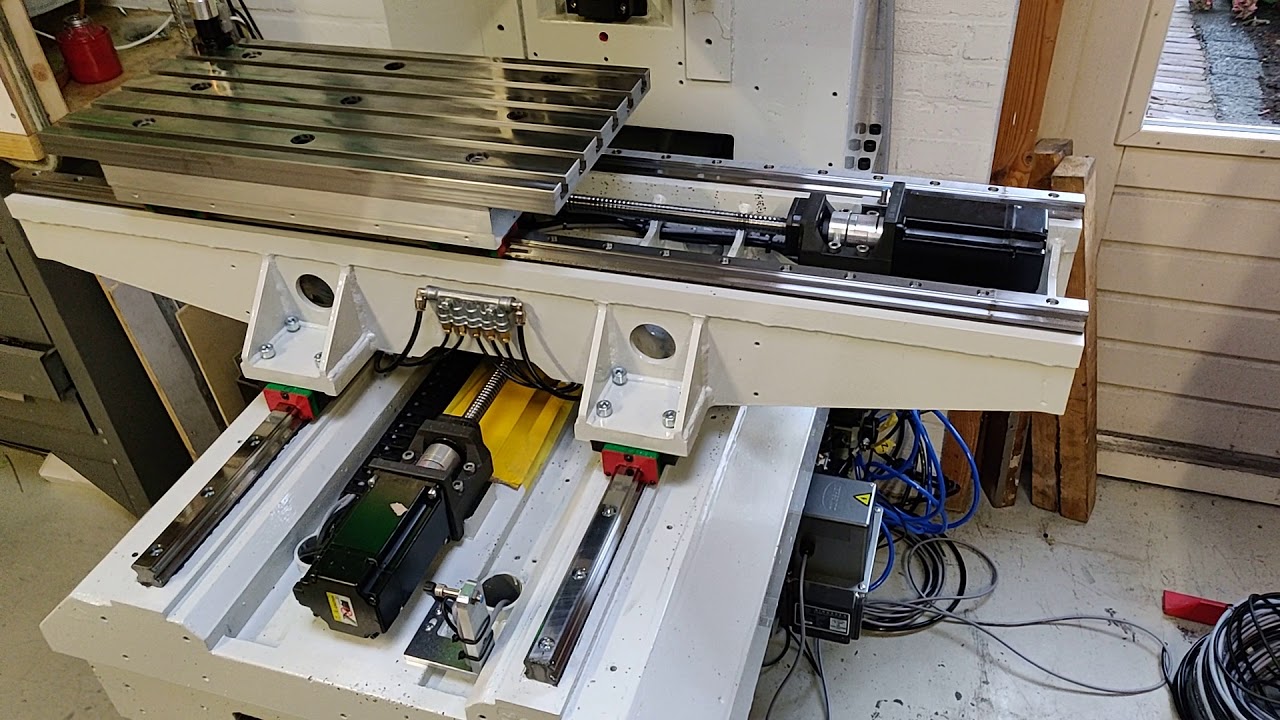

环氧花岗岩cnc建造

买哪种环氧树脂?

由于环氧花岗岩是环氧树脂和一般沙子或其他添加剂之间的混合物,因此您通常不需要特定的环氧树脂来实现这一点。必须注意,这些 DIY 解决方案最好在用混合物制造零件或填充数控铣床或数控铣床的空腔之前小规模地试验混合物。 youtube 上有各种各样的食谱,例如cncnzone。最好的选择是在那里获得灵感。

创造最佳环氧花岗岩混合物的实验

如果您想要一台大型 CNC 机床,您需要一个坚固、抗振的底座。他们用金属制造铃铛,所以如果你想要一些不会摇晃的东西,那可能不是最好的。环氧花岗岩是您最好的选择,但哪种环氧花岗岩最好?这就是问题[亚当本德] 在一系列实验中回答 这导致了一台外观精美的数控机床。

虽然这是一个为 CNC 机床完成基础的项目,但它也是一个实验,以确定创建您自己的环氧花岗岩的最佳配方。实验的目的是有效地确定最好看的环氧花岗岩,并在该复合材料的组成中使用四个变量。使用沙子、砾石、染料(以氧化铁和液态环氧树脂染料的形式)和两部分环氧树脂来制作七种不同的样品。使用岩石的样品并没有那么好,而且仍然有空气滞留。即使将环氧树脂放入真空室进行脱气也是如此。最终获胜的组合是 80% 沙子和 20% 环氧树脂与少许黑色染料的混合物,在 DIY 振动台上振动 30 分钟。

Hackaday – Adam Bender – 创造最佳环氧树脂花岗岩的实验

结论

环氧树脂花岗岩是制作 DIY 数控机床的绝佳材料。它坚固、耐用且看起来很棒。但是,它可能既昂贵又困难,但在某些情况下很容易使用。但是,如果您准备好迎接挑战,环氧花岗岩绝对值得您在下一个项目中考虑。尽管不要忘记诸如混凝土/ UHPC之类的替代品,因为它们也具有非常有前途的特性。

45-60GPa这是正常范围,选择普通骨料即可。关键是你是否做后处理、加热等。

但如果要达到75GPa以上,所有骨料都要经过专门挑选,并且要特别注意后处理的方式,可能需要一定的压力储存一段时间。但目前还没有一家公司能够非常确定的完成这个值,需要不断的测试和调整,偶尔也有少数能够达到,并且没有100%保证他们能够达到这个实力。

感谢您的见解!

在我用环氧树脂花岗岩为我的数控铣床制作了 3 个部件(底座、塔架和床身)后,我再也不会使用环氧树脂了。它很难加工,价格昂贵,很难获得良好的表面光洁度。需要振动台等,到处乱七八糟,很难清洁。后来我当然发现了uhpc。但看看它是多么容易使用,便宜,表面光洁度好,90-150 mpa,易于清洁。这对我的下一个项目来说是理所当然的。您可以便宜地买到预混合袋。

它比传统的钢材要好得多。但不是最好的。