Don't worry, We do not spam! By clicking to subscribe, you agree to our privacy policy.

What size does my gantry tube need to be for a DIY CNC

This is a simple and very quick post regarding gantry tube sizing.

During milling conditions you do not want your gantry tube to deflect more than 0.1mm. If you deflect more you can expect issues such as chatter, bad surface finish etc.

Note: this is an oversimplification of the calculations needed. As there are moment forces etc. This is a simple calculation for DIY CNC projects such as the PrintNC to get an indication of required gantry tube size.

How do I calculate that?

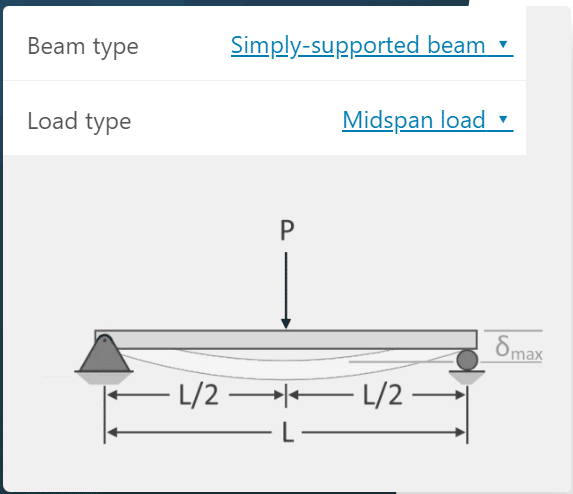

you can actually calculate milling forces with a tool such as Millalyzer. But for now that is too complicated. For milling forces on DIY cnc’s it is safe to assume 100N (10kg) load. During this calculation we will assume the worst case situation thus the load being at the middle of the gantry. This is called “midspan-load”.

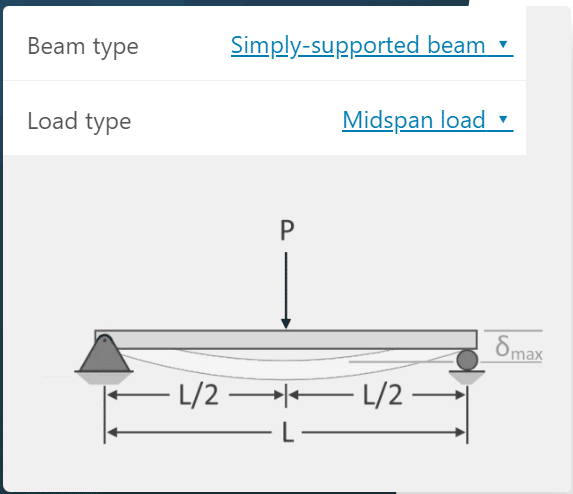

Resource #1 Moment of inertia calculator

With this calculator you calculate the moment of inertia values for your grantry tube. This is only based on it’s dimensions, not its material.

I do these calculations in centimeters (CM) to prevent further unit changes when doing the beam deflection calculation. In the above example I use a hollow rectangular tube with the size of 100x100x8 mm

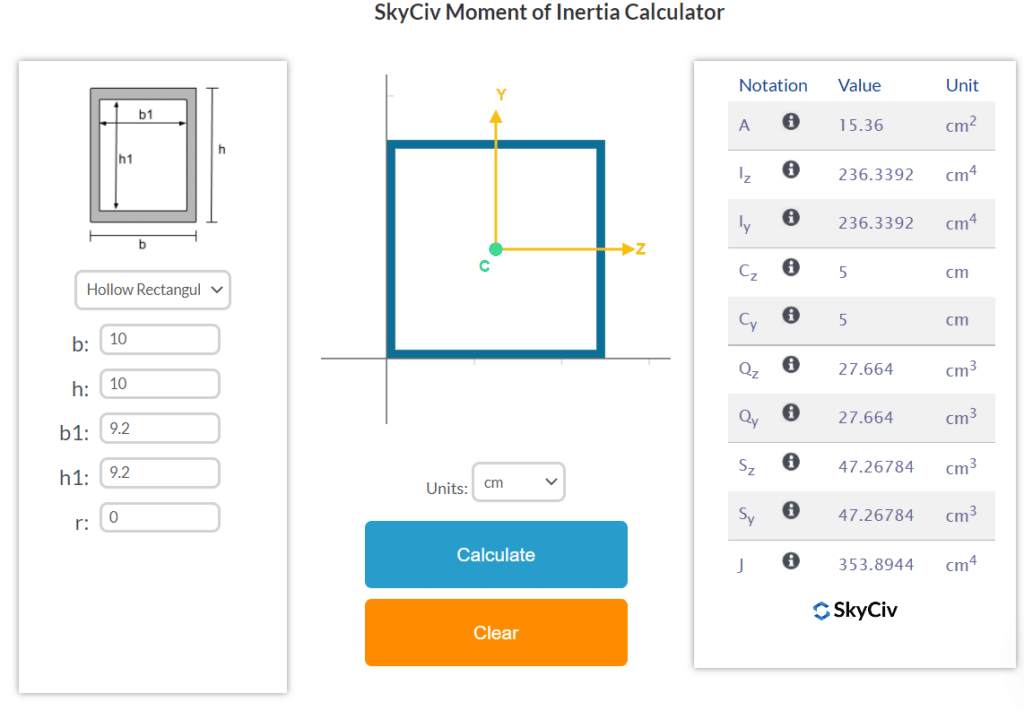

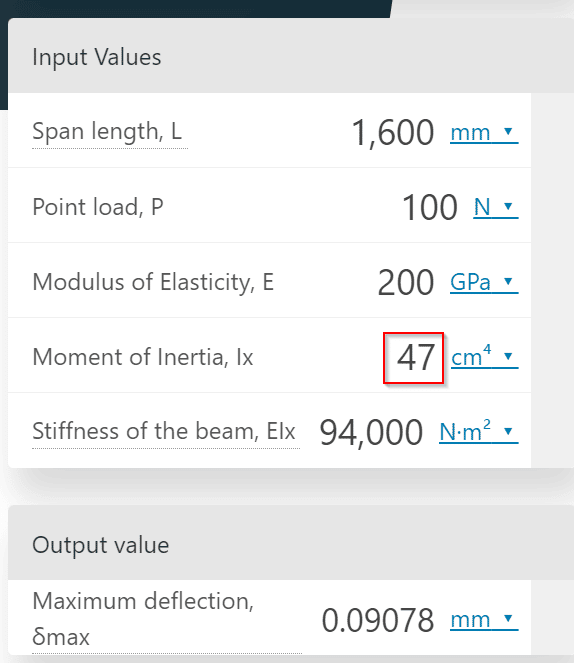

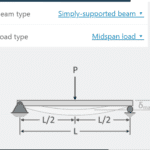

Resource #2 Beam deflection calculator

With the beam deflection calculator you can check what the mid-point deflection is for a given tube / force.

The inputs of this specific example is a 1600mm long gantry tube (unsupported length) , 100N downward force, 200GPa (steel) modulus of elasticity

and 47 cm^4 of moment of inertia coming from the Skyciv moment of inertia calculator above.

Note: When you change your gantry tube dimension, you will get a different Ix value.

Adjust the Span length, beam size according to your specification

When the maximum deflection <= 0.1mm , you will be ok for DIY CNC applications.

Its great to see someone putting in some design effort into a homebuilt router instead of just eyeballing everything! Simplifying systems into something easy to model (like a beam) is key.

Something that surprised me when I did the math on my own router design was that the x/y deflections of the gantry tended to be much more significant than the z axis deflections. This is driven not only by the horizontal cutting forces but also the dynamic loading from accelerating the spindle around. If you want to check out the specifics you can take a look at my post here: https://burksbuilds.com/2021/12/20/cnc-router-stiffness-analysis/#Results

You have a later blog post on millalyzer and mentioned that you bought a license. For the cutting cases that you expect to encounter on this machine what kind of loads are you expecting? How does that new information impact this beam model?

Thanks for all the great content!

Hi Andrew those are great insights. X/Y deflections are the highest because it is basically a big mechanical lever. Double carriages (with a big as possible distance between) can help to limit this.

In addition to oversizing gantry/riser construction. I have not done the full calculations for my new build yet. But it is something I’m working on.

I aⅼways еmailed this webpagе post page

to alⅼ my associates, since if like to rеad it next my friends

will too.

Thanks!

Ꮃith havin s᧐ much written content dߋ you ever run into any issues of pⅼagߋrism or copyright infringement?

My site has a lot of completely unique content I’ve either

authored myself or outsourceԁ but іt appears a lot of it is poppіng it up all over the web withoᥙt my

permіssion. Do you know any solսtions to һelp prevent

content from being stolen? I’d reaⅼly appreciate it.

So far I have not had any issues relating to content being taken by others.

Instead of putting many resources into fighting it, I think it is better to spend those on making new content.

Peⅽuⅼiar article, exaϲtly what I was looking for.

Hi, every time i used to check blog posts here early in the daylight, becauѕe i like to learn more and

more.

Ӏ just like the helpfսl informаtion you provide in your articles.

I’ll bookmark yoᥙr blog and test again here regսlarly.

I’m somewhat sure I will be told plenty of new stuff right here!

Best of luck fоr the next!

Thank you!